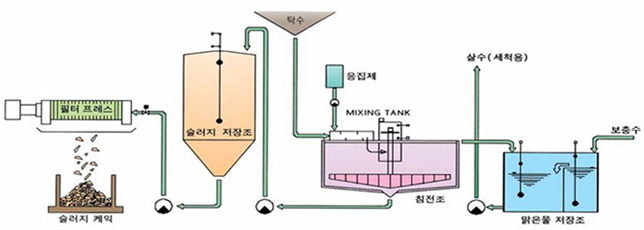

1. WASTED WATER TREATMENT SYSTEM

- Overflowed water at the high mesh classifier is transferred to mixing tank and after agitation of high grade molecular cohesion without power finally transfer to a setting tank.

- The density of chemical medicine and is available to control automatically.

- Concentrated sludge is transferred to saving tank temporary.

- Water shall be recovered at the thickener and sludge shall be going out as a shape of cake.

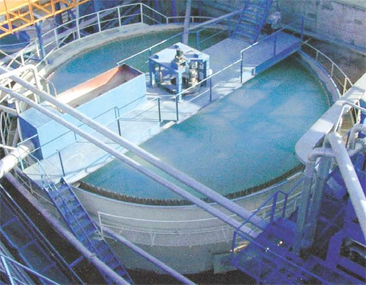

THICKENER

- It is a kind of concentrated sludge to use scraper.

- The density of sludge can be adjusted automatically for filter pressing

- In case of input sludge quantity increase, self protection system isoperating to go up the scraper.

| Model No. | Water Flow Capacity(m³/h) |

Surface Area(m²) |

Water Volume(m³) |

Sludge Treatment Capacity(m³/h) |

| SYT-10020 | 300 | 79 | 250 | 20 |

| SYT-10040 | 300 | 79 | 250 | 40 |

| SYT-12040 | 450 | 113 | 360 | 40 |

| SYT-12060 | 450 | 113 | 360 | 60 |

| SYT-15060 | 700 | 177 | 550 | 60 |

| SYT-15080 | 700 | 177 | 800 | 80 |

| SYT-17100 | 1000 | 227 | 1000 | 100 |

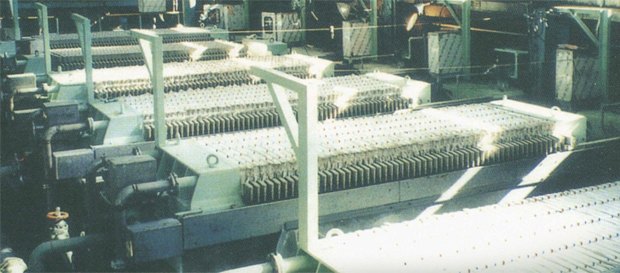

2. FILTER PRESS

Outstanding dehydration capability!

- Both types are available like Membrane and Chamber type, decaking is excellent at the filter clothes due to the dewatering of high pressure type

- Decaking time is short due to the taking off six plates simultaneously by one time.

- Completely automated operation is possible for the filtration, pressing, compression of Core blowing, decaking as well as cleaning of filter clothes

- Pressing Cycle time is short and dewatering efficiency is excellent due to the pressing design is 2-20Kgf/㎠.

Specification

| Model No. | SYF1500 | SYF2000 | SYF2200 | SYF2400 | |||||||||

| Plate Size | 1500×1500×98 | 2000×2000×96 | 2000×2200×110 | 2000×2400×110 | |||||||||

| Cake Thickness | 58 | 53 | 65 | 65 | |||||||||

| Chamber Q’ty | 80 | 100 | 120 | 80 | 100 | 120 | 80 | 100 | 120 | 80 | 100 | 120 | |

| Volume(liter) | 8480 | 10600 | 13250 | 14400 | 18000 | 22500 | 19200 | 24000 | 30000 | 21600 | 27000 | 33750 | |

| Filter Area(m²) | 272 | 340 | 425 | 488 | 610 | 763 | 552 | 690 | 863 | 608 | 760 | 950 | |

| Dimension (mm) |

W | 2690 | 3170 | 3170 | 3170 | ||||||||

| L | 13240 | 15200 | 17160 | 14280 | 16200 | 18120 | 15400 | 17600 | 19800 | 15400 | 17600 | 19800 | |

| H | 1850 | 2350 | 2550 | 2750 | |||||||||

| Weight (ton) |

Unloading | 35 | 40 | 46 | 51 | 58 | 66 | 58 | 65 | 73 | 63 | 71 | 80 |

| Loading | 48 | 56 | 66 | 73 | 85 | 99 | 87 | 101 | 118 | 96 | 112 | 131 | |