UNITEC Crushing equipment is proud to introduce this UNITEC Quadroll hydraulic crusher to the Australian Quarrying, Mining and Recycling industries.

1. UNITEC Quadroll Crusher details

- All fine crushing after Jaw Crusher is carried out by only 1 UNITEC Quadroll crusher for production of manufactured sand.

- Main Applications

- Producing under 5mm Fine Sand (Input size 9-25mm).

- Producing under 13mm (Input under 40mm).

- Or other fine crushing requirements for construction materials.

- Processing of recycled waste such as construction waste materials and bricks, fine concrete and asphalt aggregates.

- Fine mineral production like Gold, Silver, Lead, Zinc, Copper, Diamond, etc.

- Advantages

- High efficiency and performance.

- High capacity and productivity with low wear parts costs.

- Up to 70% lowest wear cost than impact crushers and cone crushers in particular application.

- Easy replacement of wear parts.

2. WHAT IS A QUADROLL CRUSHER

General Description

The UNITEC Quadrolls is a compression type rolls crusher which is fitted with two pairs of heavy duty counter rotating rollers, arranged such that one pair of rollers sits above the other. In this configuration, feed material entering the crusher is effectively crushed twice in each pass through the Quadrolls.

The UNITEC Quadrolls is designed as a fine reduction crusher to fill the gap between

conventional cone crushers and the “super fine” performance of the High Pressure

Grinding Rolls machine (HPGR). The Quadrolls is not an HPGR and should not be operated in the same manner as an HPGR.

3. RANGE OF QUADROLLS CRUSHERS

There are four models available as follows.

3 – 1. MODELS

|

Model |

Size |

Capacity |

Max, |

RPM |

Power |

HYD.MOTOR |

|

U-HQRC |

0608 |

See Below |

25 |

100 |

75KW*4P |

ME600B |

|

0810 |

30 |

100 |

90KW*4P |

ME850B |

||

|

1012 |

35 |

100 |

110KW*4P |

ME1300A |

||

|

1215 |

40 |

90 |

130KW*4P |

ME1300A |

3-2. STANDARD CAPACITY

|

MODEL |

Bottom Roll |

Crushing Capacity (t/h)-Throughput |

||||||||

|

Setting |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

|

Φ600 * 800L |

29 |

43 |

58 |

72 |

87 |

101 |

116 |

130 |

145 |

|

|

Φ850 * 1000L |

51 |

77 |

103 |

128 |

154 |

179 |

205 |

231 |

256 |

|

|

Φ1050 * 1200L |

72 |

109 |

145 |

181 |

217 |

253 |

290 |

326 |

362 |

|

|

Φ1200 * 1500L |

98 |

147 |

195 |

244 |

293 |

342 |

391 |

440 |

489 |

|

NOTES. Capacity is based on the conditions that unit volume weight is 1.6t/m3(with grain size less

than discharge setting not included)and that feed material having compressive strength

ranging from 1,000kg/cm2 to 1,250kg/cm2 This material should be fed into crusher uniformly and

continuously in quantity and grain size. The above theoretical data is based on Limestone

Of medium hardness.

4. Installed Site (Concrete Recycling Site)

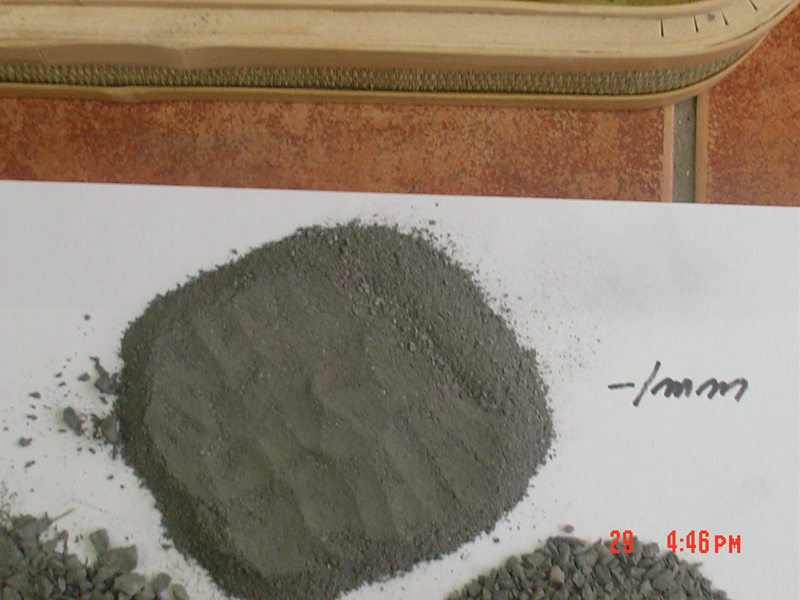

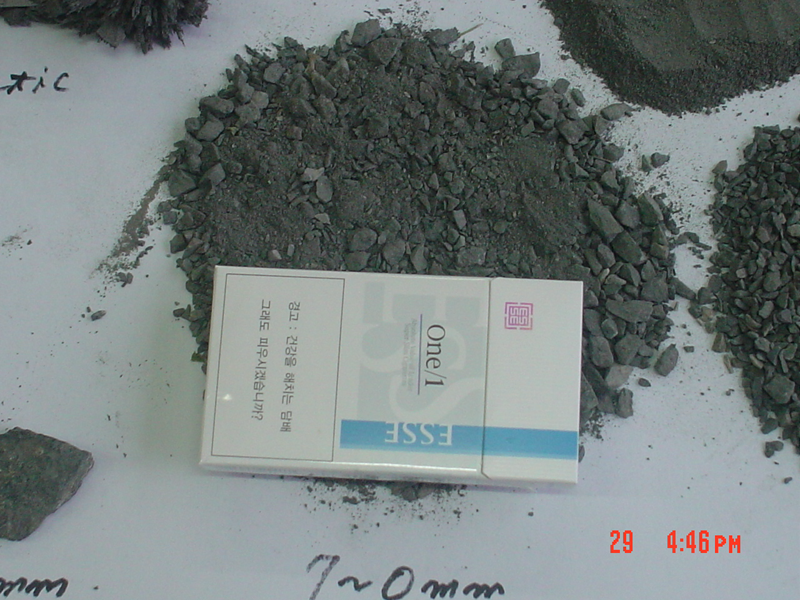

Tested Sample – Iron Ore

- Amount: Approx. 6-7 Ton

- Tested Crusher Model: U-HQRC1012

- Raw Material: Iron Ore (S. Korea)

- Fe 62.7% & Sio2 5.3% & Al2O3 1.2% & P 0.416% & S 0.066%